CNC Production Machining

CNC Production Machining

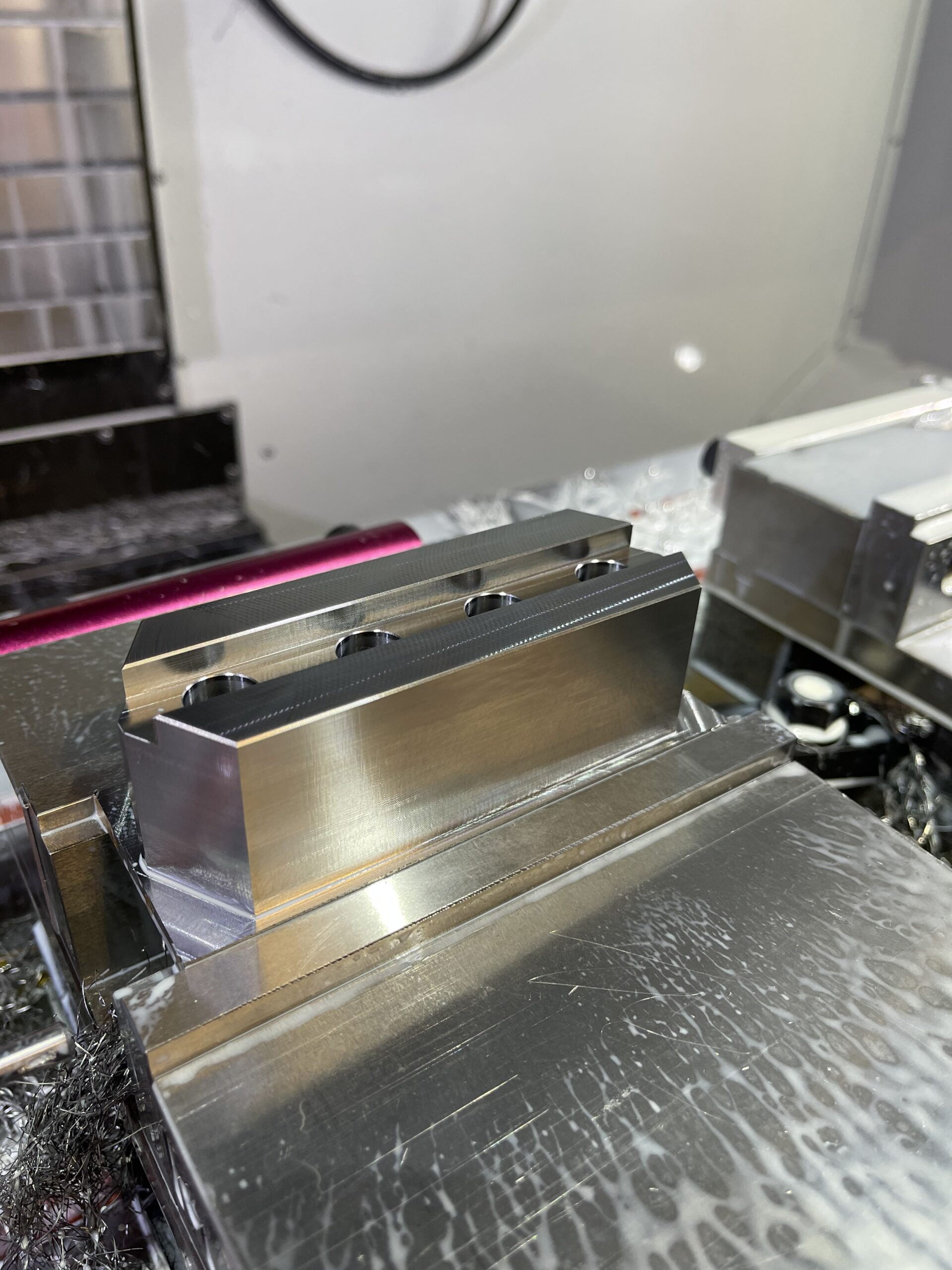

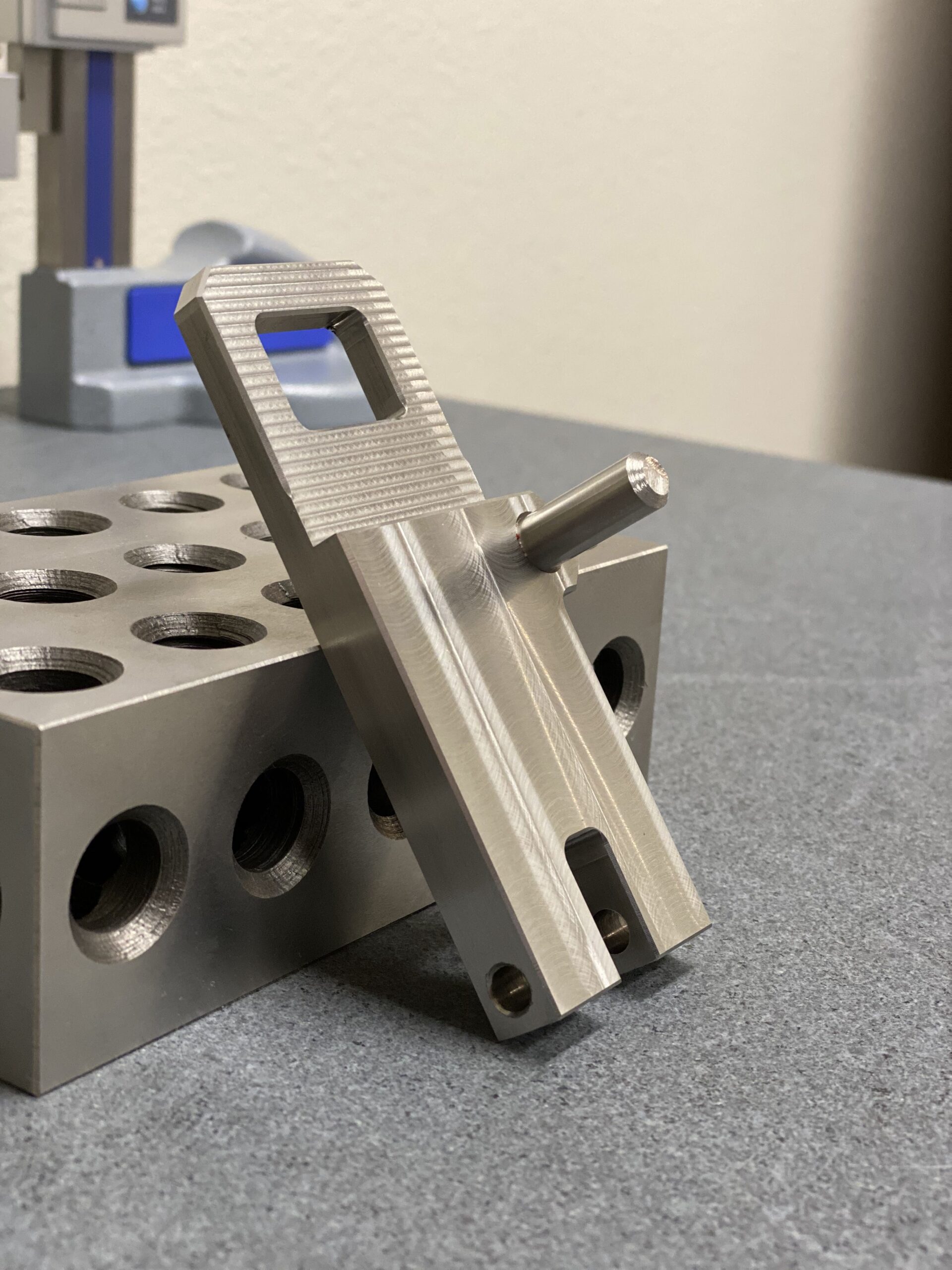

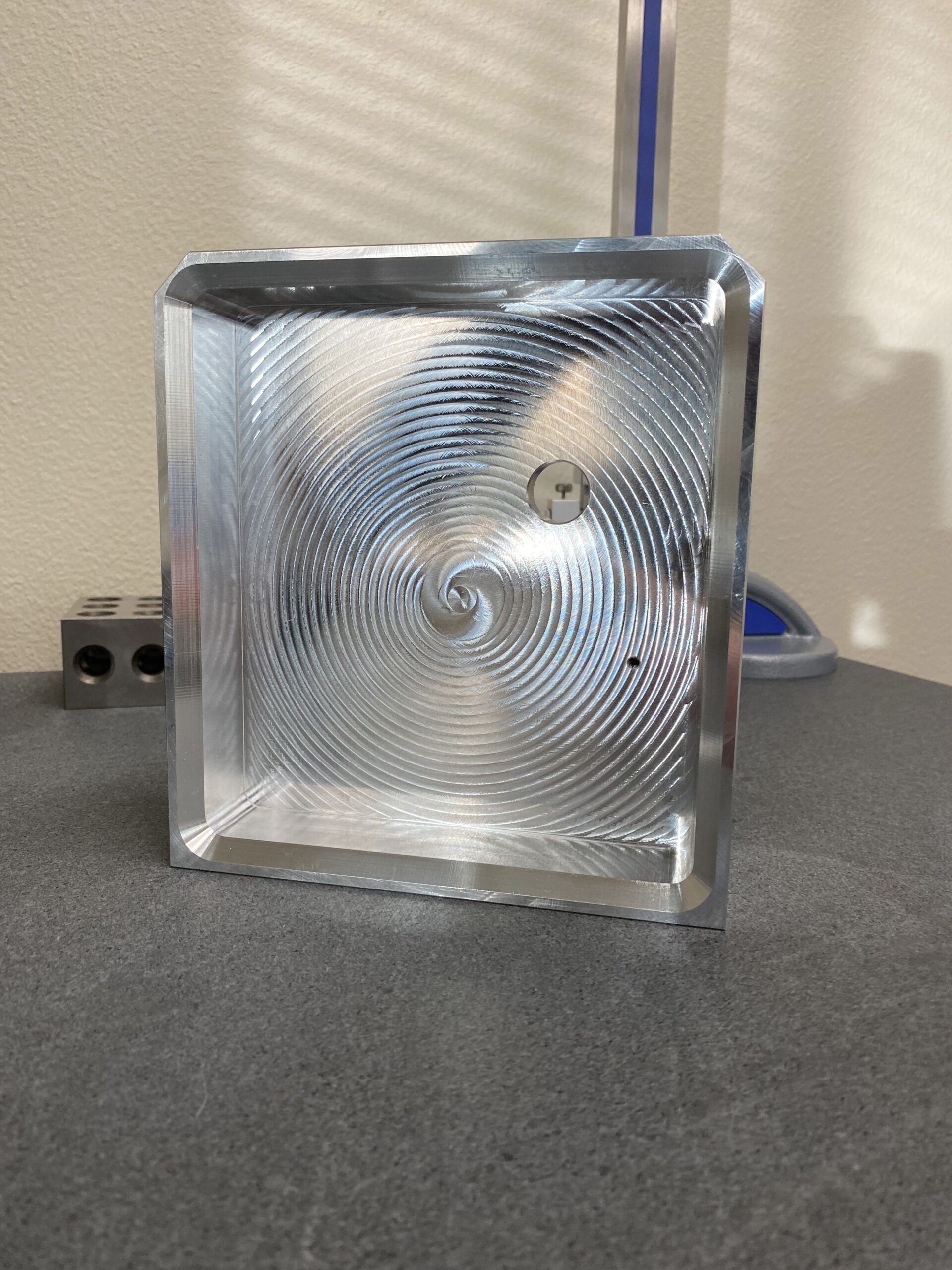

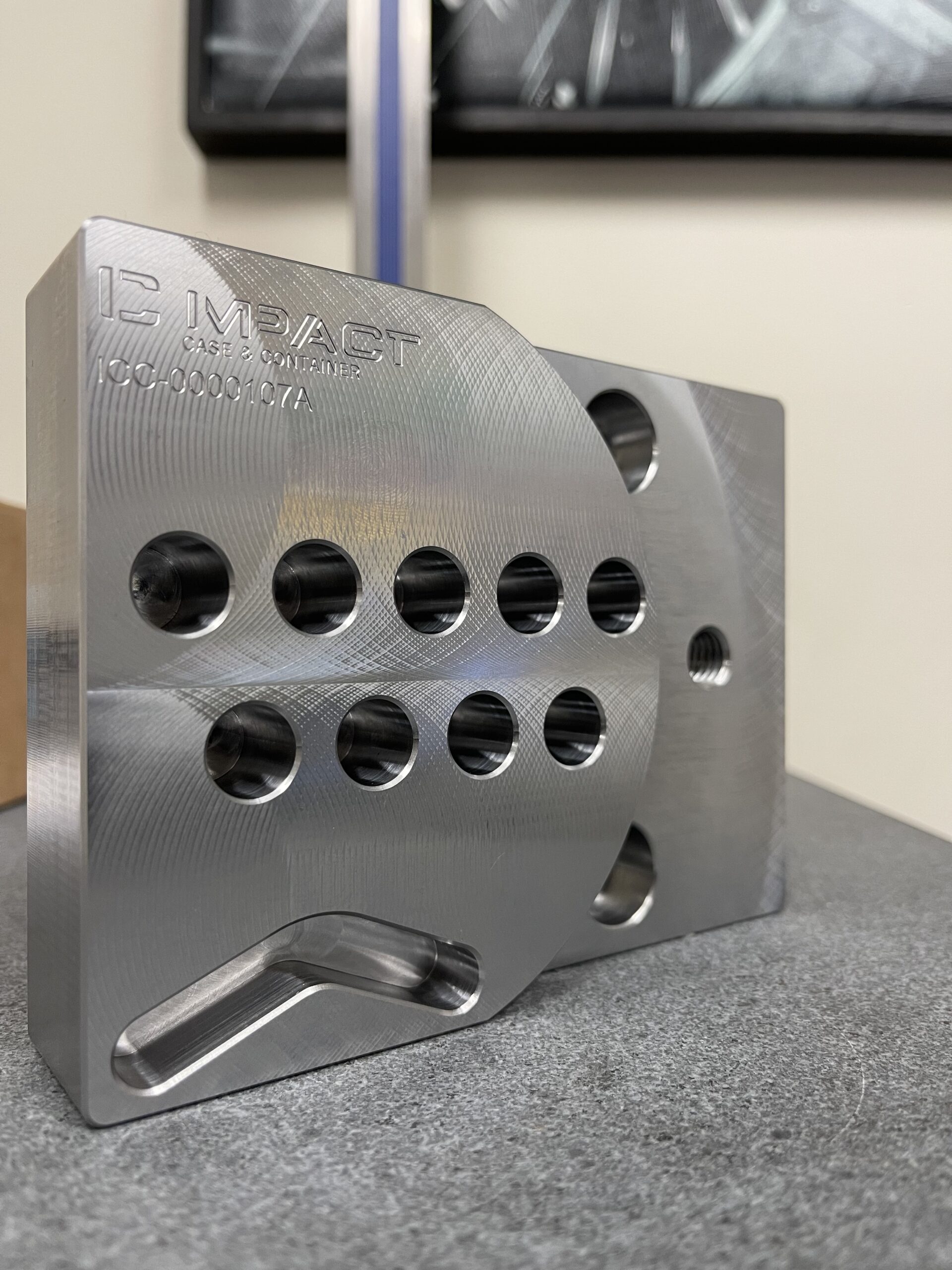

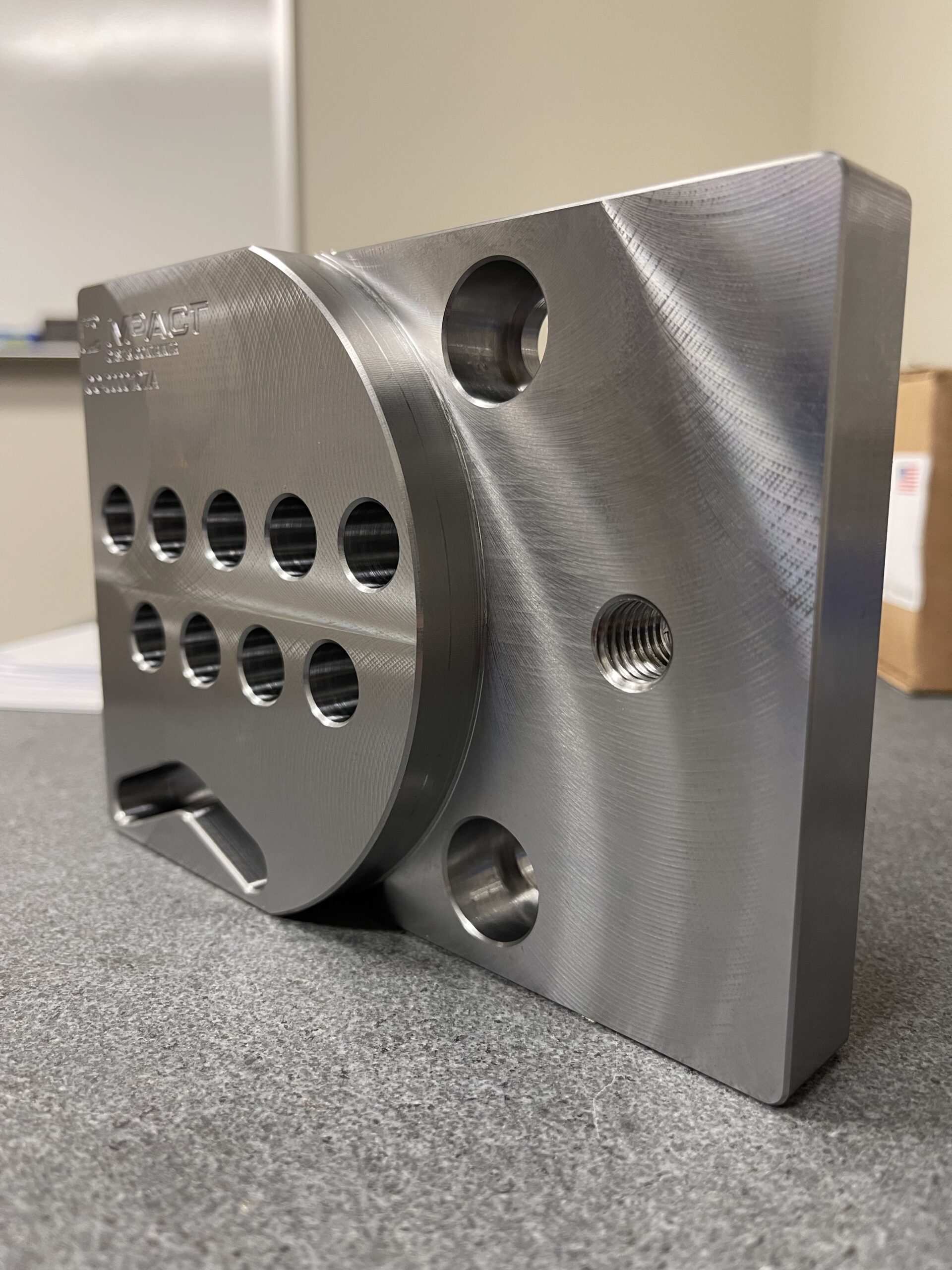

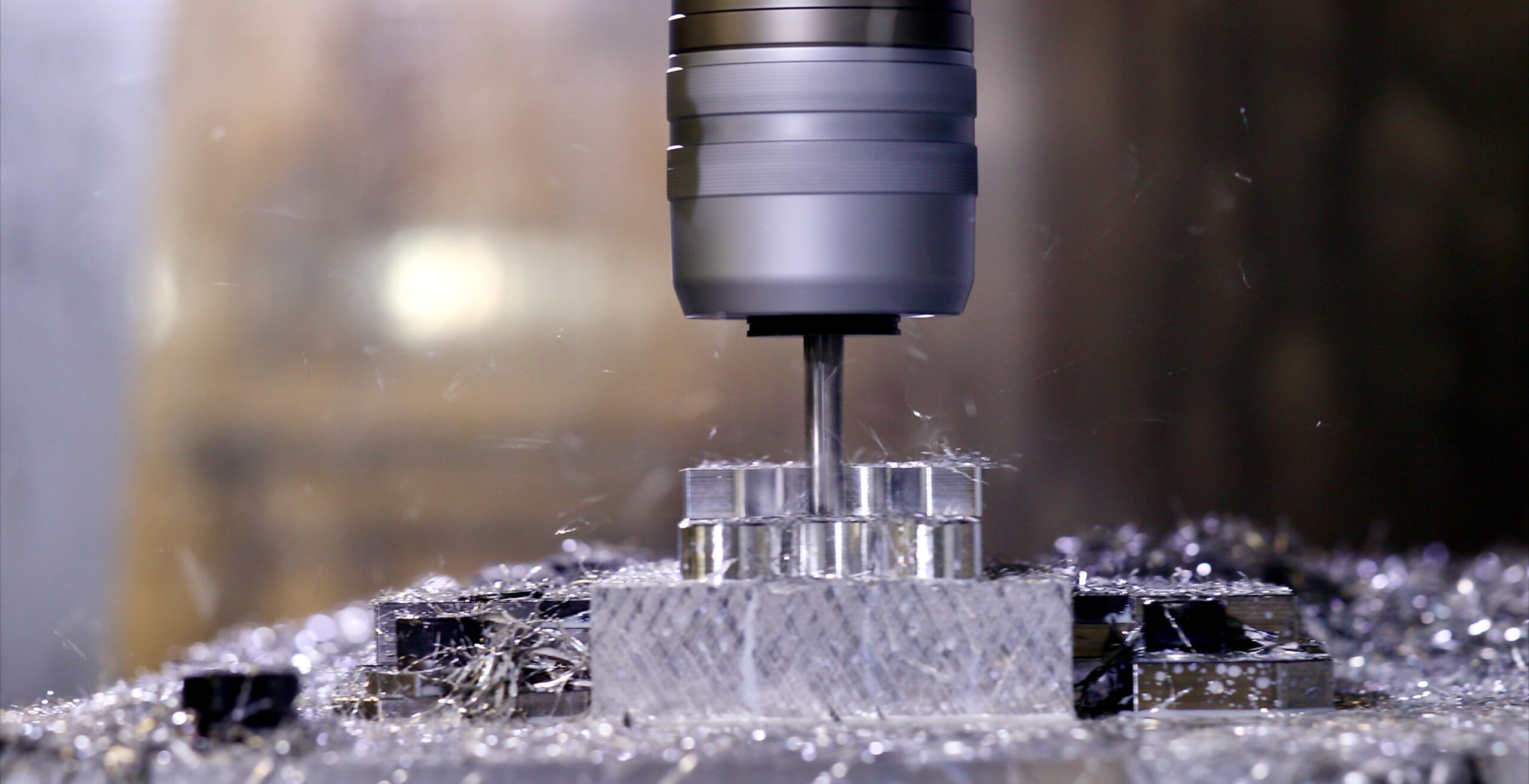

Impact Case & Container’s CNC machine shop is renowned for its quality, efficiency, and consistency across a range of production runs, from small batches to large scale production.

We excel at low-volume, one-off machining, which frequently requires a high level of skill on the part of our machinists. We utilize a variety of data sources to quickly produce the parts our customers require. We follow the same success principles for non-production machining as we do for CNC production machining.

We are constantly investing in cutting-edge technology and staffing our shop with the industry’s best and brightest. We are well-known for assisting clients in overcoming a wide variety of unique obstacles.

Let's start your next project together!

Contact the team at Impact Case & Container to get started on your next project!