Aerospace Aluminum Cases

Custom Aluminum Aerospace Cases

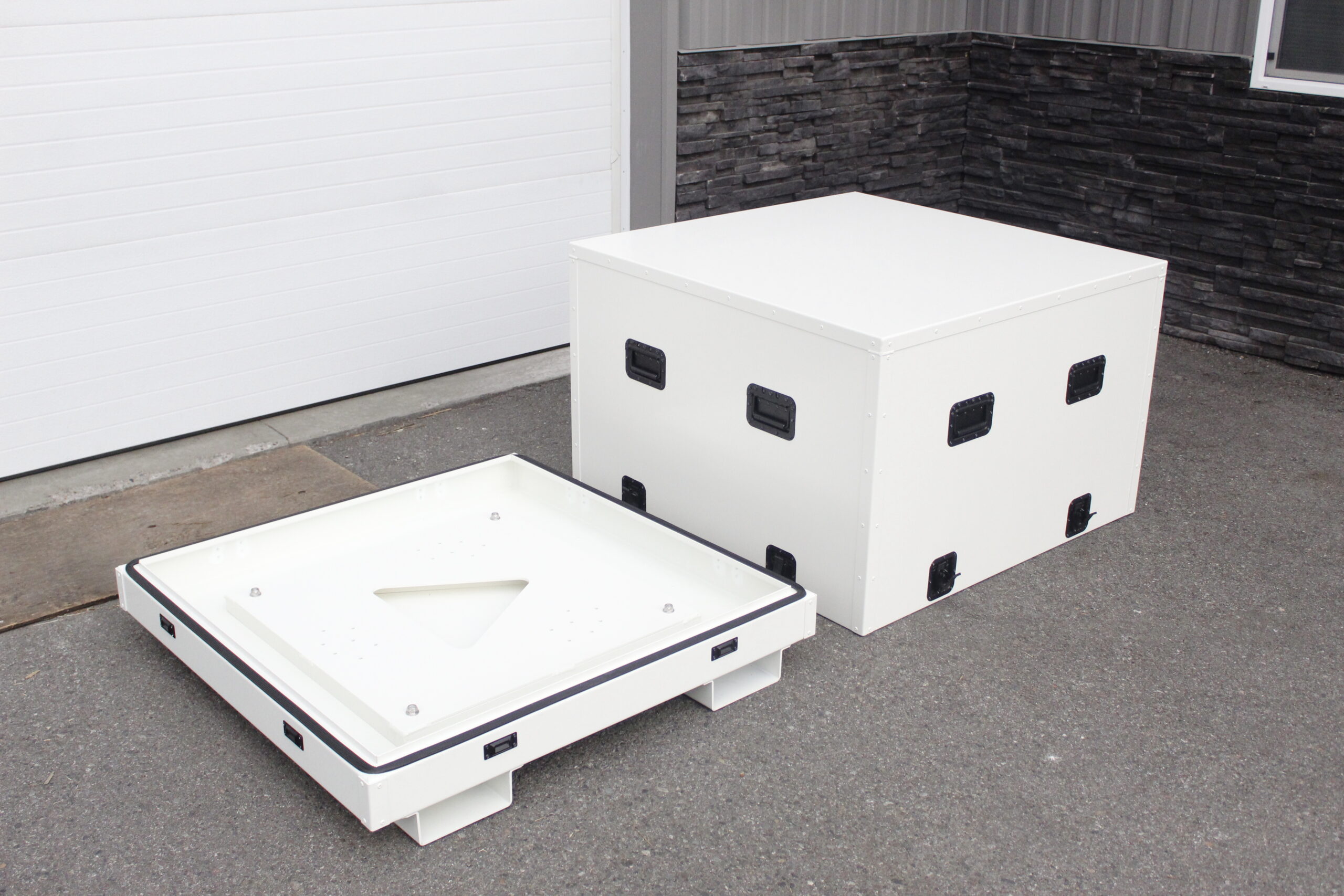

Impact Case & Container supplies cost-saving reusable containers to move high-value parts from one supplier to another safely. ICC Aerospace case and containers provide superior protection for all types of sensitive equipment, parts and toolkits.

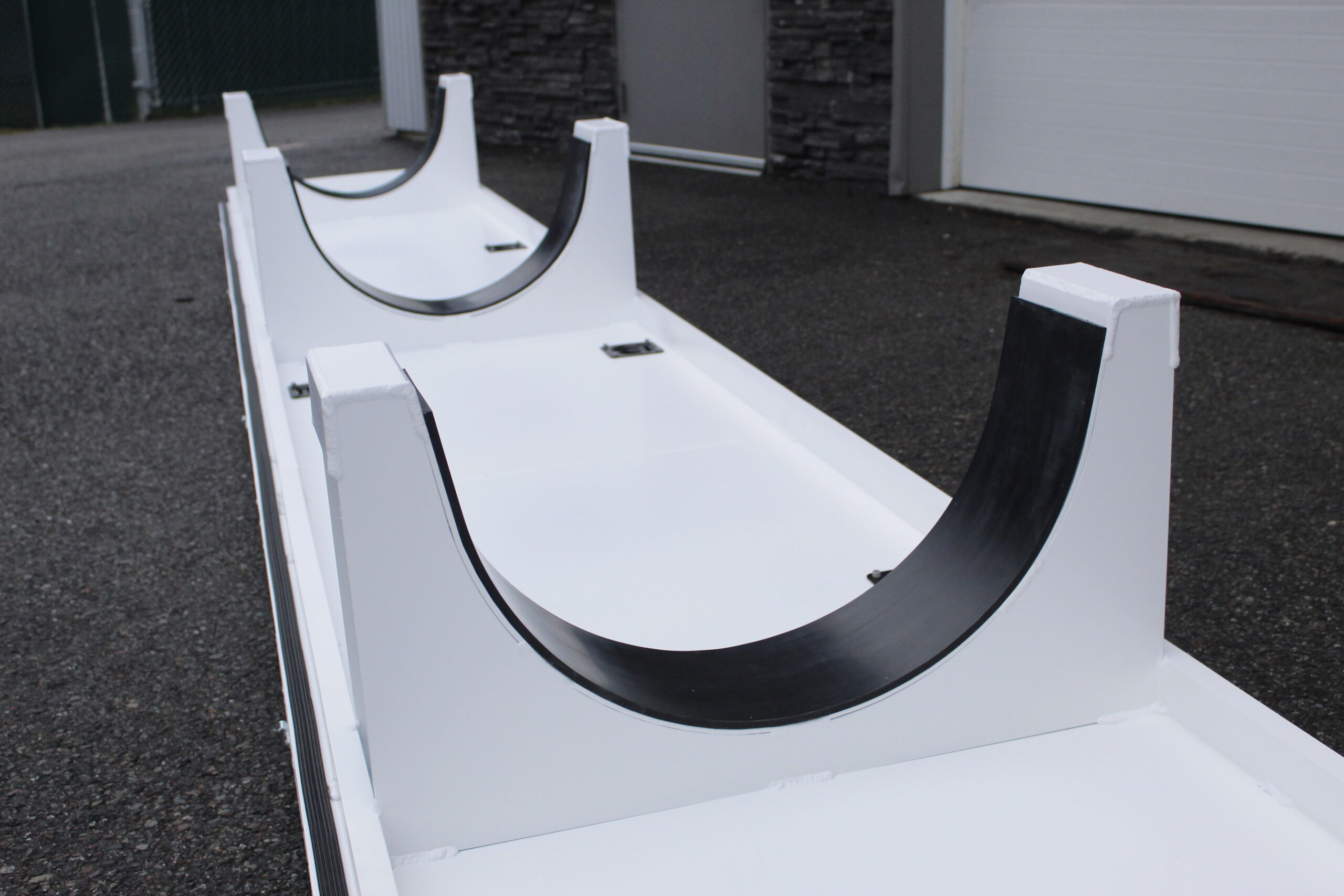

Impact Case & Container aerospace aluminum cases & containers are custom built to house sensitive parts and equipment including helicopter blades, fuel tanks, cockpit assemblies, gearboxes, and engine assemblies. At ICC, we understand the importance of keeping delicate testing equipment within proper calibration specifications during transit. Certified packaging engineers design and manufacture precision foam inserts guaranteed to securely hold and protect the specialized devices and equipment.

ICC also designs and builds casing and container systems to house various maintenance equipment and toolkits. All casing systems are custom designed to be user-friendly, lightweight, and portable. With features that include recessed wheels, retractable pull handles, stacking corners, removable trays, and foam that can be customized to include part numbers and color-coding.

At ICC, we understand the importance of brand awareness. Our cases are designed with custom powder coating to add custom graphics and logos to any case or container.

Aerospace Aluminum Cases Built

To The Highest Standards in Workmanship.

From initial design through all facets of manufacturing, an ICC case is built to surpass the highest standards in workmanship. For twenty years, our expertly crafted cases have continued to go beyond the status quo and set new standards in functionality and durability. From OEM cases to national retailers to government custom protective solutions, we can make it happen.

A fully-custom fabricated aluminum protective case from ICC is reusable, reparable, highly-specialized and completely recyclable at the end of service. Our knowledgeable team of case designers and engineers use advanced and reliable manufacturing methods in conjunction with superior raw materials to produce cases of true distinction.

The ICC manufacturing facility is located in the heart of the Idaho panhandle and features the latest advances in computer-controlled punch and form fabrication equipment.

Why Custom Aluminum Cases

Lighter, stronger, and more cost-effective – what more could you ask for in a reusable protective case or container solution? Custom aluminum cases are very lightweight and offer real advantages over traditional plastic cases.

ICC’s sustainable aluminum cases are unaffected by extreme heat or cold conditions and regularly perform between -238°F to +302°F.

Aluminum cases require no molds or special tooling, saving time and money. Our cases are incredibly strong and resistant to impacts. Impacts may show on the exterior, but the energy from the impact is absorbed within the distortion and not transferred to the contents.